MAGPIE MACHINING & MANUFACTURING

MACHINE LIST & CAPABILITIES

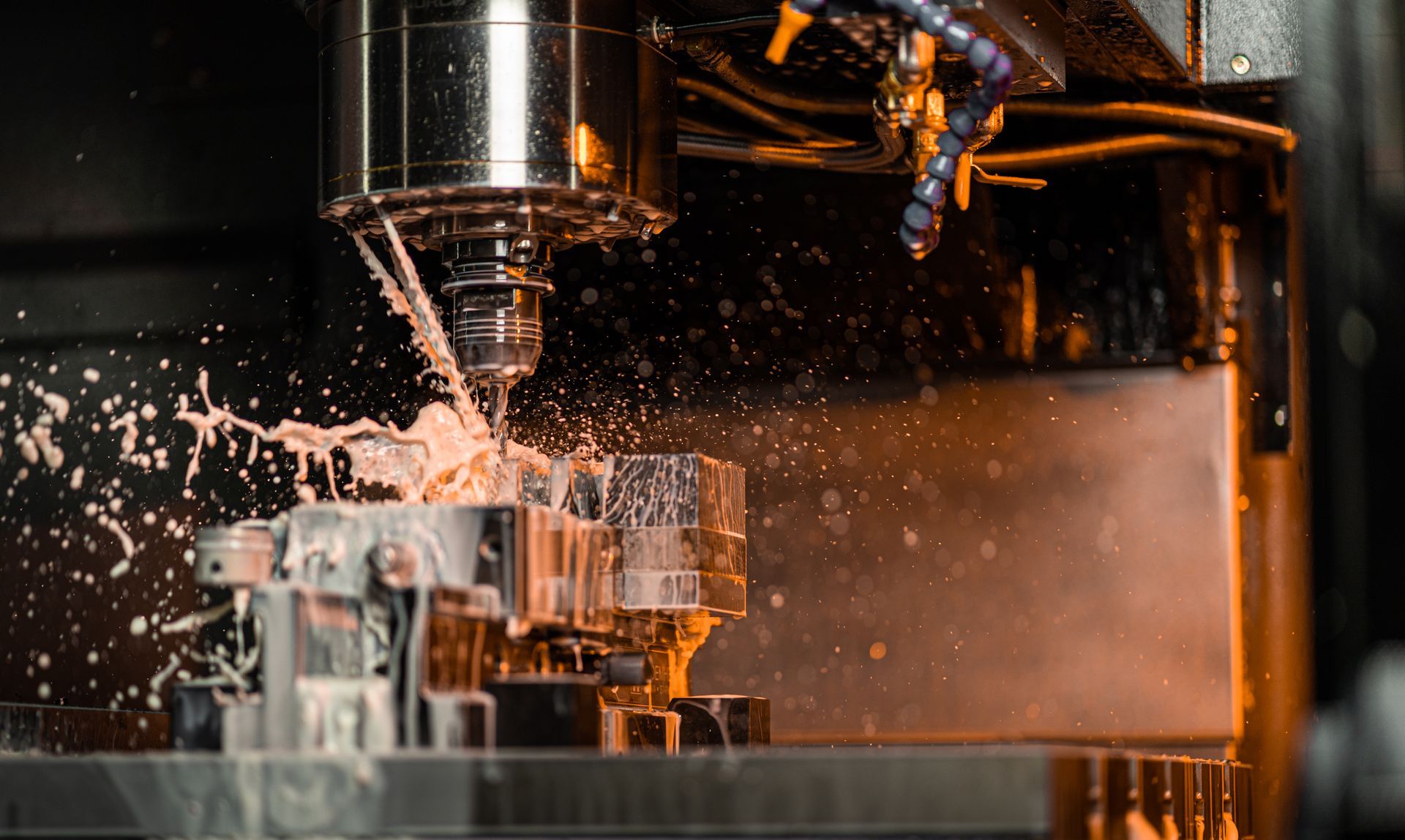

STATE-OF-THE-ART MANUFACTURING

Machine Shop Equipment & Capabilites

Magpie Machining & Manufacturing is a precision machine shop located in Rock Hill, South Carolina. We are committed to providing you with superior service for your parts and components needs. Our modern equipment combined with our expert machinists gets you the parts you need the first time, on-time, every time! Here is a list of our state-of-the-art equipment and machinery:

- Mori Seiki MV50 40" x 20" x 24" 8k spindle Vertical Machining Center

- Milltronics VM20 40" x 20" x 28" 15K spindle Vertical Machining Center

- Mori Seiki Frontier L1 8 " chuck up to 9" turning Diameter 5C High Speed collet chuck

- Okomato 6" x 12" Linear Surface Grinder 9" x 16" Horizontal Bandsaw

- Doosan DNM4500 Machining Center with 15K Spindle

- Wia Hyundai 5600 42" x 22" x 24" milling capabilities

- Doall continental 12" Bar/Diameter production Band Saw

- Deckel Maho DMU50 3+2 Five Axis Machine Center

- Hyundai Wia 2600SY Multi Axis Live Tooling Turning Center up to 10" diameter

- Okomato 10x 24 Automatic Surface Grinder

Have an idea? You conceive it and we will build it—satisfaction guaranteed!

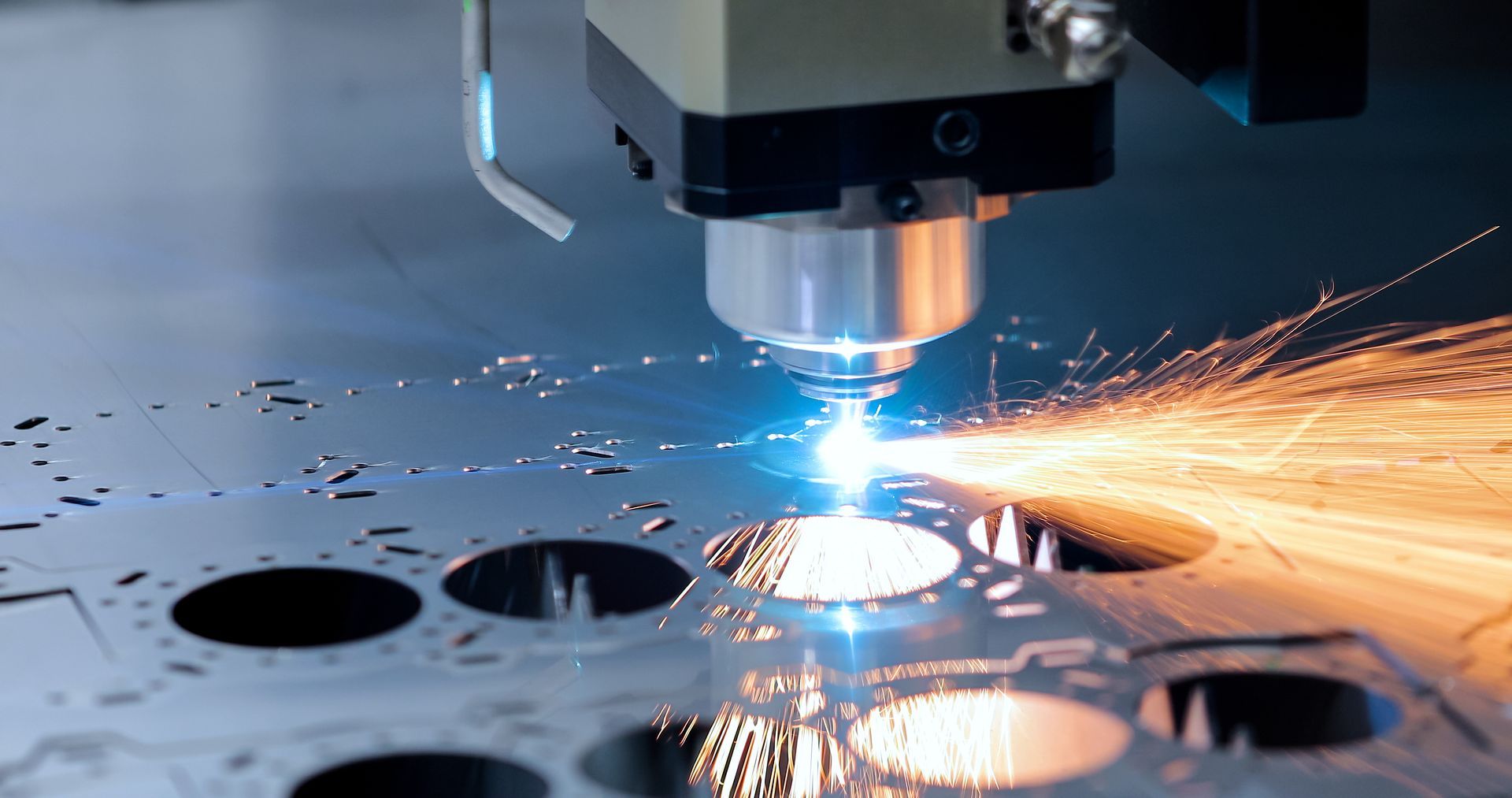

If you’re sourcing precision parts, you’ve likely encountered both CNC machining and laser CNC cutting . While both use computer-controlled precision, they are very different manufacturing processes with distinct strengths.Choosing the correct process affects part performance, cost, lead time, and manufacturability . Understanding these differences upfront helps avoid redesigns and unnecessary expense. This guide explains how CNC machining and laser CNC differ—and how to determine which process is right for your project. What Is CNC Machining? CNC machining (Computer Numerical Control machining) is a subtractive manufacturing process that removes material from a solid block using mechanical cutting tools such as mills, drills, and lathes. The machine follows programmed tool paths to produce highly accurate, three-dimensional parts. CNC Machining Capabilities CNC machining is best suited for: 3D components with depth and thickness Tight tolerances and precision fits Structural or load-bearing parts Complex geometries and internal features Common machined features include: Threads and tapped holes Pockets, cavities, and slots Precision mating surfaces Chamfers, fillets, and contours CNC Machining Materials CNC machining supports a wide range of materials, including: Aluminum Steel and stainless steel Brass and copper Engineering plastics (Delrin, nylon, UHMW) Specialty and high-strength alloys If your part must withstand force, align precisely, or function mechanically , CNC machining is typically the best option. What Is Laser CNC Cutting? Laser CNC , commonly referred to as laser cutting , uses a high-powered laser to cut material through focused heat rather than physical contact. The laser melts or vaporizes material along a programmed path, making it ideal for fast and accurate 2D cutting. Laser CNC Capabilities Laser cutting is best suited for: Flat or sheet-based parts Thin to medium material thickness Complex 2D outlines and profiles High repeatability and fast turnaround Typical laser-cut applications include: Brackets and plates Sheet metal components Panels, shims, and gaskets Decorative or branded metal parts Laser CNC Materials Laser cutting commonly works with: Steel and stainless steel sheet Aluminum sheet (thickness dependent) Brass and copper (specialized setups) Plastics and acrylics Because there is no physical tool contact, laser cutting minimizes mechanical stress and eliminates tool wear. CNC Machining vs. Laser CNC: Key Differences Manufacturing Method CNC Machining: Mechanical cutting Laser CNC: Thermal cutting Part Geometry CNC Machining: Full 3D parts Laser CNC: Primarily 2D, flat parts Material Thickness CNC Machining: Thin to very thick materials Laser CNC: Best for thin to medium thickness Precision Type CNC Machining: Dimensional and functional precision Laser CNC: Profile and outline precision Structural Strength CNC Machining: Excellent for load-bearing parts Laser CNC: Limited by sheet thickness Typical Use Cases CNC Machining: Functional, mechanical components Laser CNC: Sheet-based, profile-cut parts Accuracy vs. Application Both CNC machining and laser CNC are highly accurate—but accuracy alone does not determine suitability. CNC machining offers superior control over depth, perpendicularity, and surface relationships , making it ideal for parts that must fit, move, or carry load. Laser CNC excels at precise outlines and intricate profiles , but it cannot create threads, internal cavities, or complex 3D features. The correct process depends on how the part will be used , not just how accurate it needs to be. Cost, Speed, and Production Volume Laser cutting is typically: Faster for flat parts More cost-effective for simple or high-volume profiles Ideal for repeatable sheet metal production CNC machining is typically: Slower per part More flexible for design changes Better suited for low-to-medium volumes of complex parts Many projects use both processes together , such as laser cutting a blank and CNC machining precision features afterward. Which Process Should You Choose? Choose CNC machining if your part: Requires thickness or depth Needs threads, pockets, or precision fits Must handle mechanical loads Choose laser CNC if your part: Is flat or sheet-based Has complex outlines or cutouts Requires fast, repeatable production If you’re unsure, early input from a machining partner can prevent costly revisions later. Why Choosing the Right Process Matters Selecting the correct manufacturing method from the start helps: Reduce material waste and cost Improve part performance Shorten lead times Eliminate redesigns Precision manufacturing is as much about process selection as it is about machine capability. Final Takeaway CNC machining and laser CNC cutting are complementary technologies , not competitors. Each excels when applied correctly. When your manufacturing partner understands both processes and applies them strategically, you get parts that meet your functional requirements without unnecessary compromise.

When it comes to CNC machining and rapid prototyping, Protolabs is a name you’ll see often. They’ve built a reputation as a global digital manufacturer with automated quoting systems, fast production capabilities, and a large footprint. For many engineers, startups, and product developers, Protolabs looks like an easy option. But bigger doesn’t always mean better. If you’ve ever worked with a massive online manufacturer, you’ve likely experienced the trade-offs that come with scale : less personalized service, limited flexibility, and a sense that your project is just another job in the system. That’s why more companies are turning to Magpie Machining —a dedicated precision machine shop where personal attention, speed, and quality consistency are built into every project. Here’s how Magpie stacks up against Protolabs. 1. Automated vs. Hands-On Protolabs is known for its automated quoting system , which can generate instant pricing and lead times. It’s a useful feature—but it comes with limitations. Automated quotes don’t account for nuanced details, design suggestions, or potential issues that could save time and money down the road. Magpie Machining, on the other hand, takes a hands-on approach . When you submit a project, an experienced machinist actually looks at your design, evaluates manufacturability, and works with you to get the best possible outcome. That means: Real feedback, not just a computer estimate. Opportunities to optimize design and reduce cost. A partner who understands the why behind your part, not just the what. For engineers who value collaboration, Magpie’s approach is more than a quote—it’s a conversation. 2. Speed and Flexibility Protolabs has built its brand around speed, offering rapid prototyping in as little as 1–3 days for certain processes. But here’s the catch: those timelines are based on standardized setups and rigid parameters. If your project falls outside their system, timelines can stretch and costs can climb quickly. Magpie Machining is built to be fast and flexible . Because we’re a smaller, agile shop, we can pivot quickly when your project changes, adjust setups, and push urgent jobs to the front of the line. That’s the kind of flexibility you don’t get with a company processing thousands of orders daily. Need a prototype turned around in a matter of days—not weeks? Magpie makes it happen, without the red tape. 3. Personal Service vs. Customer Portals With Protolabs, most communication happens through online dashboards and automated emails. That might feel efficient, but when problems or questions arise, it can leave you feeling stuck in a support loop. At Magpie, you can pick up the phone and talk directly to the machinist working on your part . You’ll know the name of the person cutting your components, inspecting them, and packaging them. That personal connection builds trust and gives you confidence that your project is in good hands. When you need answers, you won’t be waiting for a ticket number—you’ll be speaking directly with the people making your parts. 4. Consistency and Quality Control Protolabs operates across multiple facilities worldwide. While they maintain strong quality standards, the sheer scale of their operations can introduce inconsistencies between runs. One batch may look slightly different from the next, especially when parts are routed to different facilities. Magpie Machining ensures consistency from job to job . The same team, same machines, and same inspection process handle your parts every time. For industries where precision matters—medical devices, robotics, aerospace—that kind of repeatable quality is essential. 5. Local Accountability Protolabs is a global company, which can be both a strength and a weakness. While they can handle huge order volumes, accountability often feels distant. If something goes wrong, your issue is one among thousands in a corporate system. Magpie Machining offers local accountability . We don’t hide behind dashboards or layers of corporate processes. If there’s an issue, we fix it—fast. Our success is tied directly to your satisfaction, and we take that responsibility seriously. 6. Cost Transparency Protolabs’ pricing is competitive, but it’s also rigid. Their automated quotes don’t leave much room for creative problem-solving or cost optimization. Magpie Machining provides transparent, competitive pricing with the added value of custom advice. We’ll look for ways to reduce unnecessary machining steps, adjust tolerances where possible, and help you balance cost with performance. That means you’re not just buying parts—you’re buying efficiency. 7. Building a Long-Term Partnership At Protolabs, your project is one of thousands. At Magpie Machining, your project is a priority. We work with many clients from their very first prototype all the way to scaled production runs, building trust and consistency along the way. By choosing Magpie, you’re not just getting parts—you’re building a partnership that grows with your business. The Verdict: Magpie Machining vs. Protolabs Protolabs is a powerful option for certain types of projects. If you want standardized parts through an automated system, they deliver on speed and scalability. But when your project requires personal attention, flexibility, and a true machining partner , Magpie Machining is the smarter choice. Here’s the bottom line: Protolabs : Large, automated, efficient—but impersonal and rigid. Magpie Machining : Agile, responsive, personal, and invested in your success. When you need more than just a part number—when you need a partner who knows your name and cares about your project— Magpie Machining delivers. Ready to see the difference for yourself? 👉 Request a Quote Today

In today’s manufacturing world, speed and precision are everything. Engineers, startups, and established companies alike depend on machining partners who can not only deliver accurate parts but also adapt quickly when projects change. With so many options available, it can be tempting to turn to large online marketplaces like Xometry . They promise convenience, instant quotes, and a network of suppliers. But here’s the question: does bigger always mean better? If you’ve ever felt like a “small fish in a big pond” working with large online services, you already know the answer. That’s where Magpie Machining stands apart. By offering a faster turnaround, personal customer service, and hands-on expertise , Magpie delivers a better experience from start to finish. Let’s take a closer look at the differences. 1. The Marketplace vs. The Partner Xometry is essentially a middleman. They connect your order to a vast network of suppliers, acting as a broker between you and whoever happens to take the job. While this model may sound efficient, it often introduces challenges: Inconsistent quality depending on which vendor gets assigned. Limited control over production timelines. Difficulty building a long-term relationship with a shop that truly understands your needs. Magpie Machining , on the other hand, is not a faceless marketplace. We’re a dedicated precision machining shop . When you work with us, you know exactly who is making your parts, inspecting them, and ensuring they meet your exact specifications. There’s no guessing, no bouncing between vendors, and no compromises. With Magpie, you’re not just placing an order—you’re gaining a partner . 2. Faster Turnaround, Real Communication Xometry’s quoting engine is fast, but quoting isn’t the same thing as producing. Because Xometry has to distribute work across different vendors, turnaround times can be unpredictable. Some projects get delayed simply because the assigned vendor is backed up, and you often won’t know until it’s too late. Magpie Machining operates differently. As a smaller, agile shop , we pride ourselves on being responsive and fast. Need a prototype turned around in days, not weeks? We make it happen. Have last-minute changes? We adjust right away. And unlike a giant platform, you’re never stuck waiting for a generic support email. You can pick up the phone and talk directly to the machinist working on your job. That personal touch means fewer delays, fewer surprises, and a lot more confidence. 3. Consistency You Can Trust With Xometry, your parts could be made by one vendor this time and a completely different vendor the next. Even if both follow the same drawings, small variations in machines, setups, and inspection standards can creep in. If your project requires multiple runs, that inconsistency can cause big headaches. Magpie Machining removes that uncertainty. We own our process from start to finish , using state-of-the-art equipment, careful inspection, and a skilled team committed to your success. Every job is run with the same attention to detail, so you know you’re getting repeatable quality, batch after batch. For industries where precision and reliability matter—medical, aerospace, defense, robotics—that consistency makes all the difference. 4. The Value of Personal Service Large online platforms thrive on volume. Their goal is to move as many orders as possible through the system. That means individual customers—especially smaller companies—rarely get tailored attention. At Magpie, every client matters . Whether you’re a startup developing your first prototype or an established manufacturer scaling production, we treat your project with the same level of care and urgency. You’re not just an order number; you’re a relationship we value. We take the time to understand your project goals, help with design for manufacturability (DFM), and even suggest cost-saving solutions. That kind of partnership simply doesn’t exist in a marketplace model. 5. Local Accountability vs. Distant Oversight When you work with Xometry, your parts could be manufactured across the country—or across the globe. While that may sound like access to a vast network, it also means you’re dealing with distance, time zones, and potential miscommunication . If something goes wrong, you’re stuck navigating a long support chain. Magpie Machining is local, accountable, and invested in your success. We’re not hiding behind layers of vendors and automated systems. If there’s an issue, we fix it—fast. That accountability is worth more than any instant quote engine. 6. Competitive Pricing Without the Hidden Costs On paper, Xometry can look cheaper. But once you factor in shipping delays, rejected parts, or inconsistent batches that require rework, those “savings” disappear. Magpie Machining offers competitive, transparent pricing without the hidden risks. Because we handle your project directly, there are no middleman markups, no mystery vendors, and no wasted time. Just quality machining at a fair price, delivered when you need it. 7. Building for the Future When you work with Magpie Machining, you’re building a relationship that scales with your business. Need one prototype today and a production run of hundreds tomorrow? We’ll be there every step of the way. With Xometry, you’ll always be one anonymous order among thousands. With Magpie, you’re a valued partner. That difference matters not only for your immediate project, but also for the long-term growth of your company. The Bottom Line: Magpie Machining Wins on Speed, Service, and Trust Xometry’s marketplace approach has its place—but if you’re looking for faster turnaround, personal service, and consistent quality , Magpie Machining is the clear choice. We combine the technology and expertise you’d expect from a large operation with the care, communication, and accountability that only a dedicated shop can provide. So the next time you’re weighing your options between Magpie Machining and Xometry, ask yourself this: Do I want to be an order number in a massive system? Or do I want a machining partner who knows my name, understands my project, and delivers on time—every time? At Magpie Machining, we believe the answer is simple.

The energy sector is vital in powering the world, from traditional fossil fuels to renewable sources like wind and solar. As the demand for more efficient and reliable energy grows, so does the need for precision and innovation in manufacturing components for energy infrastructure. CNC (Computer Numerical Control) machining has emerged as a key technology in this space, offering many benefits that transform how energy components are produced. Precision and Accuracy In the energy sector, precision is everything. Whether creating turbine blades for wind energy or manufacturing components for oil rigs, even the slightest deviation can lead to inefficiencies, downtime, or safety risks. CNC machining excels in delivering high levels of precision and accuracy. Automated CNC machines can manufacture parts to exact specifications with tolerances as tight as a few microns, ensuring that components fit perfectly and function as intended. This level of accuracy is particularly important in industries like nuclear and aerospace energy production, where safety and reliability are paramount. Material Versatility The energy industry uses a wide range of materials, from high-strength alloys and composites to more common metals like steel and aluminum. CNC machines can work with various materials, providing flexibility to create parts for different energy applications. Whether manufacturing corrosion-resistant components for offshore oil platforms or creating lightweight parts for solar panels, CNC machining offers the adaptability needed to meet diverse material requirements. Cost-Effective Production Cost efficiency is crucial in the energy sector, where large-scale projects often require tight budget control. CNC machining offers a cost-effective production process through automation and repeatability. Once a part design is programmed into the CNC machine, it can be produced at scale with minimal manual intervention, reducing labor costs. Additionally, the repeatability of CNC machining minimizes waste, as parts are consistently manufactured with minimal errors, leading to less material loss. Speed and Scalability Companies need to scale production quickly with the growing demand for energy solutions. CNC machining allows for rapid prototyping and production, enabling faster turnaround times from design to final product. Once a design is approved, CNC machines can quickly produce many different parts, ensuring timely delivery for energy projects. This speed and scalability are essential for keeping up with the dynamic demands of the energy market, whether for expanding a wind farm or upgrading infrastructure at a power plant. Improved Safety and Reliability Safety is a top priority in the energy sector. Components used in energy production and distribution must meet rigid safety standards. CNC machining ensures that parts are consistently manufactured to high-quality standards, reducing the risk of failure in critical systems. The reliability of CNC-manufactured parts means fewer maintenance issues and less downtime, which is especially important in industries like nuclear and oil, where failures can have catastrophic consequences. CNC machining offers significant advantages for the energy sector, from precision and material versatility to cost-effective production and improved safety. As the energy industry continues to evolve and innovate, CNC technology will play an increasingly important role in delivering the high-quality, reliable components needed to meet the world’s energy demands.

In today’s fast-paced manufacturing environment, reducing production time without compromising quality is essential. The five-axis CNC machine is one of the most significant advancements aiding this goal. Unlike traditional three-axis machines operating on the X, Y, and Z planes, five-axis CNC machines introduce two additional rotary axes, offering greater flexibility and precision. Here are a few ways this cutting-edge technology drastically reduces production time for manufacturers across various industries: 1. Eliminating Multiple Setups Traditional CNC machines often require several setups to complete a complex part. Each time a part needs to be reoriented for different cuts, the production halts, leading to downtime. With five-axis CNC machines, the additional rotational axes allow the part to be machined from nearly all angles in one setup. This means fewer interruptions and faster turnaround times. By eliminating multiple setups, manufacturers also reduce the risk of human error in part alignment, further speeding up production by minimizing the need for corrections and quality control issues. 2. Handling Complex Geometries in a Single Operation Complex parts with detailed geometries often need multiple operations on traditional machines, with each one taking time to plan and execute. Five-axis machines simplify this by allowing operators to machine complex surfaces and features in a single operation. The ability to maneuver the cutting tool freely around the part ensures that even the most complicated designs can be handled efficiently. This versatility eliminates the need to move the part between multiple machines or orientations, saving time and labor costs, and reducing the potential for production bottlenecks. 3. Improved Cutting Speeds and Efficiency The enhanced precision and control offered by five-axis CNC machines enable manufacturers to optimize cutting paths and tool angles. This reduces the time spent on each part while maintaining high-quality standards. In addition, improved cutting angles mean better tool engagement, allowing for faster material removal rates. Since five-axis machines can machine parts from multiple angles without stopping, they reduce idle time and optimize material flow. This streamlining of the production process further accelerates the manufacturing cycle. 4. Reduced Lead Time for Prototyping and Custom Orders Five-axis CNC machines are also invaluable for manufacturers who deal with prototyping or small custom orders. With traditional machines, creating a prototype or fulfilling a custom order involves lengthy setup times, especially for complex parts. Five-axis machines reduce the time spent on setup and production, allowing manufacturers to bring prototypes or custom parts to market faster. For industries where time-to-market is critical, such as aerospace, automotive, or medical device manufacturing, this reduction in lead time can make all the difference in staying ahead of the competition. 5. Better Surface Finishes, Fewer Secondary Operations Another way five-axis CNC machines save time is by producing better surface finishes, eliminating the need for secondary operations like grinding or polishing. By achieving tighter tolerances and smoother finishes during the initial cutting process, manufacturers can skip additional steps and reduce production time and costs even further. Five-axis CNC machines are revolutionizing the manufacturing industry by offering enhanced flexibility, precision, and efficiency. Investing in five-axis CNC technology is a smart move for manufacturers looking to boost productivity and reduce costs.

We offer full-service capabilities to cater to the tooling and machining needs of companies from a variety of industries. No matter the type of part, level of complexity or volume, we can help you get the parts you need. As a dependable fixture in this industry, there’s more than just a few reasons why people choose Magpie! 1. Keep Legacy Machines for Longer When you’re constantly running industrial equipment it’s only a matter of time before parts begin to deteriorate and eventually fail. This is especially true in industries where machines are put under a great deal of strain or exposed to caustic or harsh environments. When you have a trusted machine that has performed well, the last thing you want to do is completely replace it because a part has failed or is failing. Not only that, but machines like this will cost your company a significant amount of money, so you want to make sure that replacing the machine is absolutely necessary before doing so. Rather than replacing your entire machine, we can create replacement parts for your legacy machines or equipment. Through reverse engineering, we can create exact replicas of a machine’s original part, allowing you to extend the life of your capital equipment and machinery. 2. No Order Minimums Oftentimes, suppliers and manufacturers will have order minimums, requiring you to order more of a part than what you actually need. This means that you may end up spending more than you want to just to meet that minimum. When working with us, there’s no order minimum since we can create even just one of the parts or components you’re in need of. So, whether you’d like a prototype or a replacement part, we can create it for you without you having to meet any kind of order minimum. 3. Take Advantage of the Latest Tech At Magpie Machining we utilize the latest in CNC machining with a five-axis DMU 50 CNC machine. This machine has an output of up to 20,000 rpm and a swivel rotary table for 5-axis simultaneous machining. With this machine you can achieve ultimate productivity and streamline your operations. Utilizing the latest in CNC machining allows us to provide you with fast turnaround times, accuracy and quality. Leveraging this type of equipment for the parts that you need ensures that you’re getting high quality parts, quickly. Rather than investing in machinery like this of your own, simply use ours! We can quickly and accurately create whatever part you need - from the highly detailed and specific to larger quantities of standard parts. At Magpie, we have the experience and state-of-the-art equipment you need for all of your tooling and machining needs. Working with us gives you a reliable, fast and cost-effective way to get the critical parts that you need. Our facility, equipment and team are capable of taking on parts regardless of the level of complexity or the size of the run, giving you an affordable way to get the parts that you need.