The Modern Machine Shop

We offer full-service capabilities to cater to the tooling and machining needs of companies from a variety of industries. No matter the type of part, level of complexity or volume, we can help you get the parts you need. As a dependable fixture in this industry, there’s more than just a few reasons why people choose Magpie!

1. Keep Legacy Machines for Longer

When you’re constantly running industrial equipment it’s only a matter of time before parts begin to deteriorate and eventually fail. This is especially true in industries where machines are put under a great deal of strain or exposed to caustic or harsh environments. When you have a trusted machine that has performed well, the last thing you want to do is completely replace it because a part has failed or is failing. Not only that, but machines like this will cost your company a significant amount of money, so you want to make sure that replacing the machine is absolutely necessary before doing so. Rather than replacing your entire machine, we can create replacement parts for your legacy machines or equipment. Through reverse engineering, we can create exact replicas of a machine’s original part, allowing you to extend the life of your capital equipment and machinery.

2. No Order Minimums

Oftentimes, suppliers and manufacturers will have order minimums, requiring you to order more of a part than what you actually need. This means that you may end up spending more than you want to just to meet that minimum. When working with us, there’s no order minimum since we can create even just one of the parts or components you’re in need of. So, whether you’d like a prototype or a replacement part, we can create it for you without you having to meet any kind of order minimum.

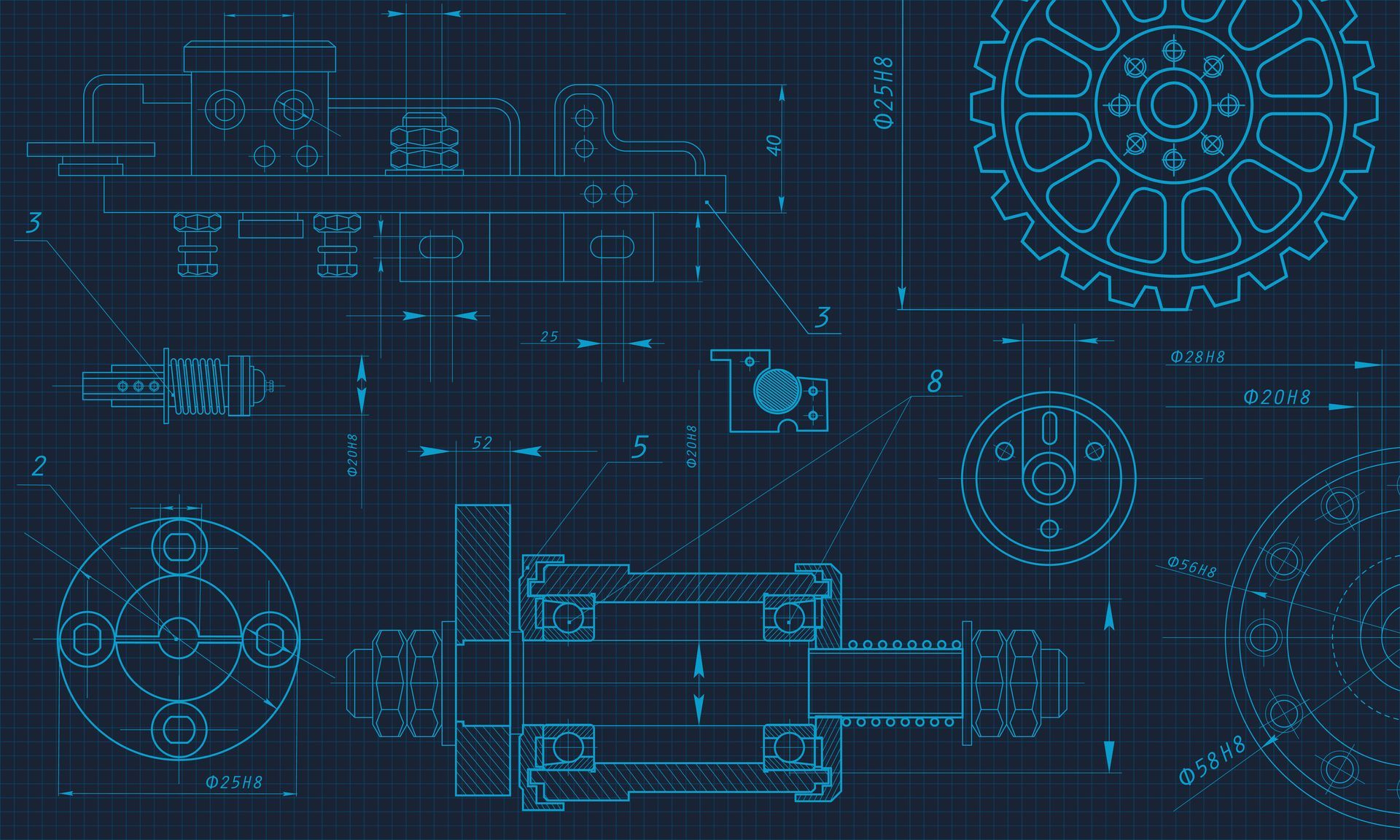

3. Take Advantage of the Latest Tech

At Magpie Machining we utilize the latest in CNC machining with a five-axis DMU 50 CNC machine. This machine has an output of up to 20,000 rpm and a swivel rotary table for 5-axis simultaneous machining. With this machine you can achieve ultimate productivity and streamline your operations. Utilizing the latest in CNC machining allows us to provide you with fast turnaround times, accuracy and quality. Leveraging this type of equipment for the parts that you need ensures that you’re getting high quality parts, quickly. Rather than investing in machinery like this of your own, simply use ours! We can quickly and accurately create whatever part you need - from the highly detailed and specific to larger quantities of standard parts.

At Magpie, we have the experience and state-of-the-art equipment you need for all of your tooling and machining needs. Working with us gives you a reliable, fast and cost-effective way to get the critical parts that you need. Our facility, equipment and team are capable of taking on parts regardless of the level of complexity or the size of the run, giving you an affordable way to get the parts that you need.

Content for MagPie Machining by Minieri & Company, LLC, Copyright © 2019-2025, All Rights Reserved.