Benefits of Five Axis CNC Machining

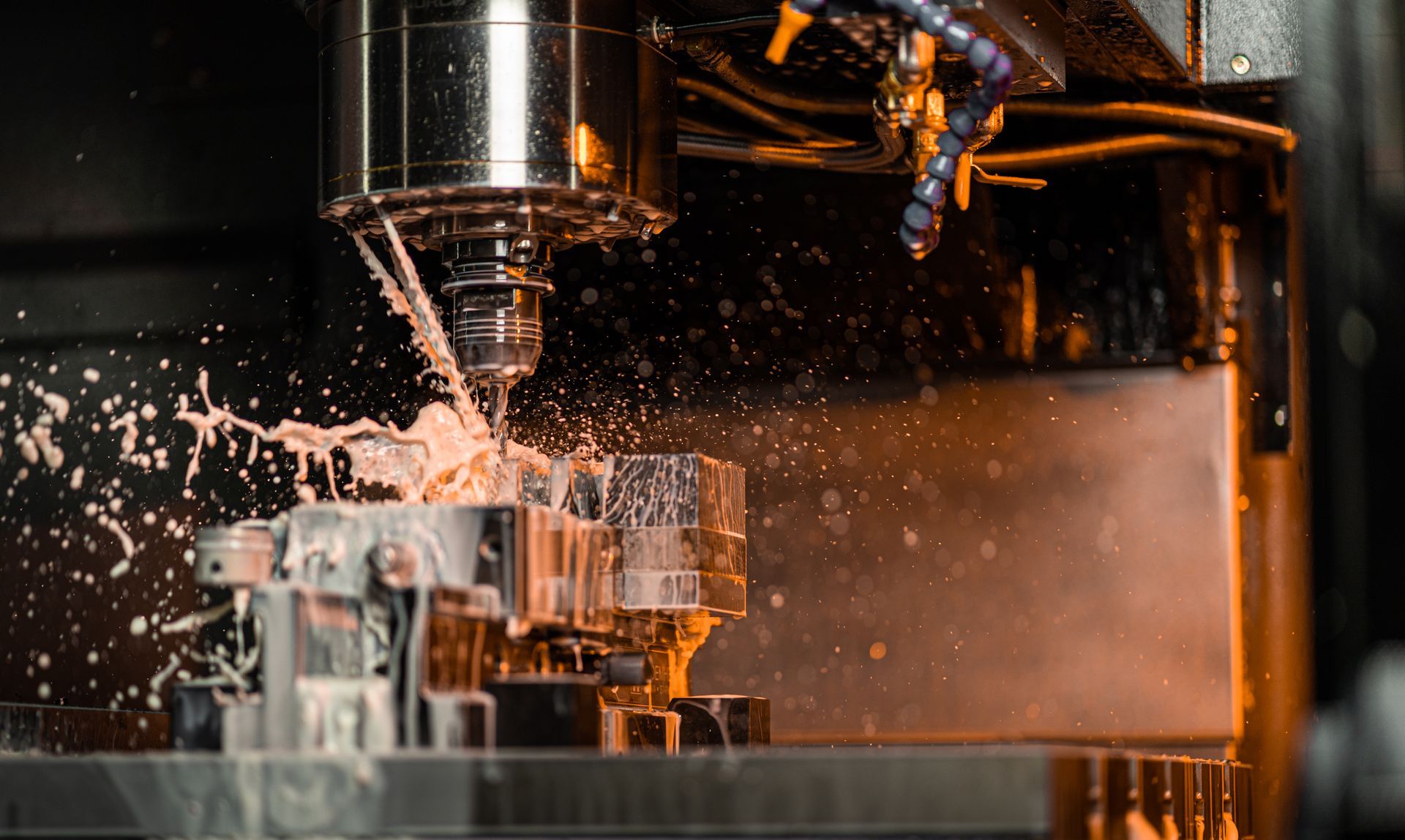

Magpie Machining utilizes the latest in CNC machining with a five-axis DMU 50 CNC machine. This machine has an output of up to 20,000 rpm and a swivel rotary table for 5-axis simultaneous machining.

CNC machines, or computer numerical control machines, are commonplace in manufacturing settings today because of the benefits they provide. In essence, CNC machines are connected and controlled by a specialized digital control system and can therefore replace much of the manual work that has to be done in manufacturing.

At Magpie Machining we utilize the latest in CNC machining with a five-axis DMU 50 CNC machine. This machine has an output of up to 20,000 rpm and a swivel rotary table for 5-axis simultaneous machining. With this machine you can achieve ultimate productivity and streamline your operations. Keep reading for some of the top benefits that you can experience when utilizing CNC machining.

Boost Productivity

When running a business, time is money. Anything you can implement to save you and your team valuable time can help your business in the long run. Traditional tooling machines require a hands-on operator in order to function. CNC machines on the other hand can operate on their own once programmed. With a CNC machine the operator doesn’t have to be hands-on the whole time and can instead focus on other revenue-generating activities.

Safety

Manufacturing can pose safety risks at times, but utilizing a CNC machine can dramatically reduce the safety risks your team is exposed to. Since traditional tooling machines are so hands-on, operators are closer to potentially dangerous machine parts. Using a CNC machine separates the operator from hazardous machine parts and allows them to monitor what’s happening at a safe distance. CNC machining also protects the operator from coming in contact with cooling fluids as well. These fluids can sometimes be hazardous if they come into contact with human skin, so minimizing exposure risk is helpful.

Reduce Errors

Traditional machining relies heavily on the operators’ knowledge and skills in order to ensure everything is set up correctly. Skilled operators can sometimes be rare, so if you have one on your team it’s best to put their expertise elsewhere. CNC machines utilize special probes that will help ensure everything is set up correctly and reduce the potential for error. A CNC machine is able to be set up more quickly than a traditional machine and will also reduce the chance of errors occurring.

Master Complexity

Complexity and precision are sometimes hard to master, especially at the same time, but a CNC machine makes mastering both of these much easier. The automation of a CNC machine removes the potential for human error and also reduces manual labor that’s required when machining a complex component. With a CNC machine you can machine complex parts in much less time and with much less labor required.

CNC machining offers a lot of benefits such as saving time, increasing safety and making it easier to create complex parts. CNC machining can help take your business to the next level by cutting down your production time and giving you a competitive edge. We can help you take advantage of the technological innovations that the DMU 50 CNC machine provides.

Content for MagPie Machining by Minieri & Company, LLC, Copyright © 2019-2025, All Rights Reserved.