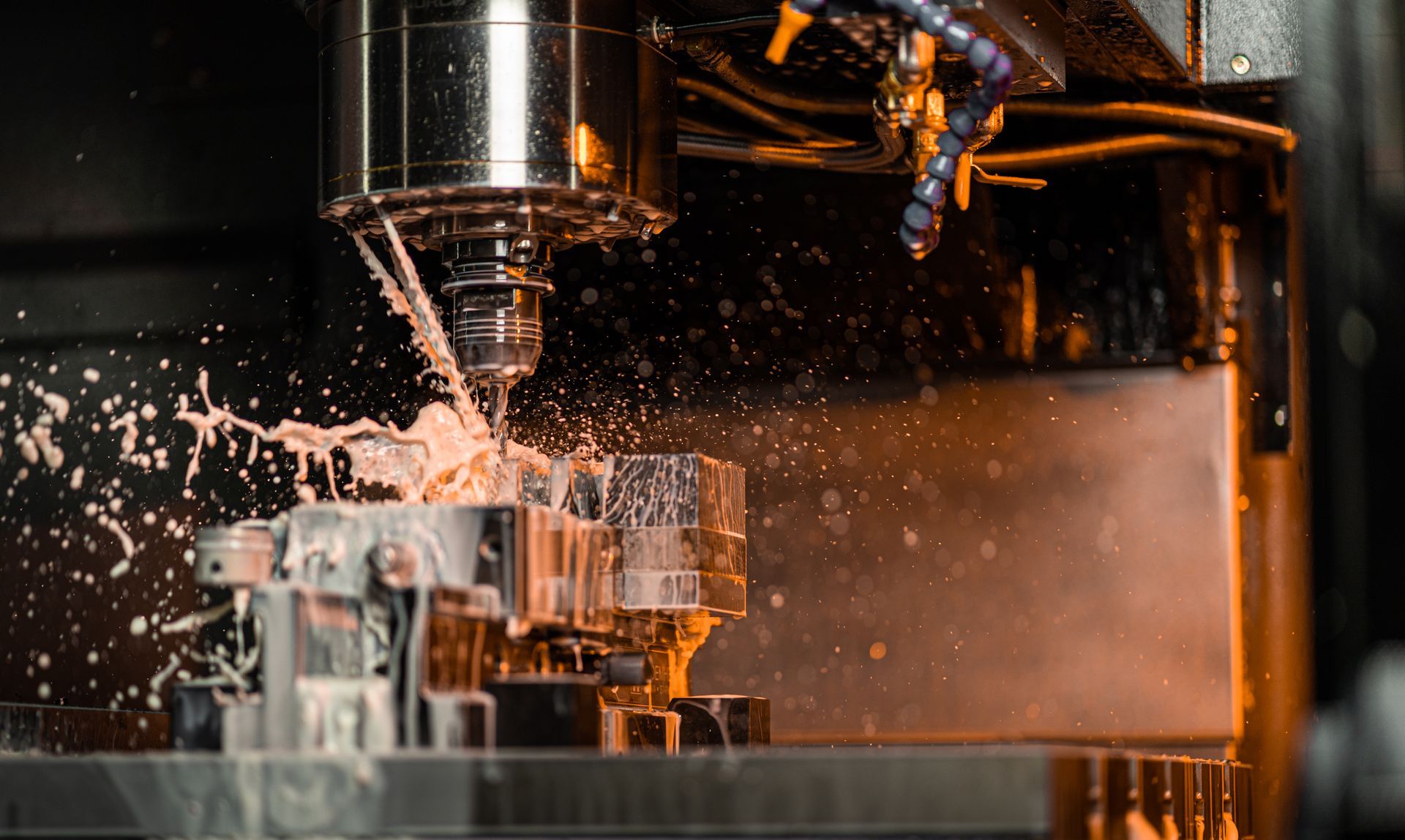

How Precision Machining is Used in the Automotive Industry

Precision parts and custom components play a huge role in the automotive industry.

Magpie Machining specializes in manufacturing precision parts and components to help your business succeed. Outsourcing your precision machining needs to us can benefit your business in many ways. By using Magpie Machining for your precision part and component needs you can save your business time, money and resources.

One of the industries we serve that benefits greatly from our manufacturing of precision parts is the automotive industry. Precision parts and custom components play a huge role in the automotive industry. We’re able to give automotive manufacturers more flexibility and efficiency with their production processes. Keep reading for some of the main reasons the automotive industry utilizes precision parts and custom components.

Constant Advancements

Companies within the automotive industry are constantly adapting and advancing. There is great pressure within this industry to stay ahead of competitors through constant innovation. Since there is such a regular need for change within the automotive industry, it can be challenging for your machinery to keep up.

Each time a new model, feature or edition is introduced, machinery often has to be updated. This is where precision parts come in. In order to adapt the manufacturing process, automotive makers require customized parts and components to fit into their existing machinery. The addition of these precision parts makes it cost effective to constantly introduce new innovations.

Lean Manufacturing

The idea of lean manufacturing that is now used across nearly every industry actually originated in the automotive industry. Precision machine parts help those in the automotive industry streamline manufacturing processes by being customized to their specific needs. Precision machine parts help ensure automotive makers that waste is minimized by crafting parts specific to how they will be incorporated into the manufacturing process. As the processes evolve with each additional innovation introduced, precision machine parts help promote lean manufacturing principles by optimizing efficiency and reducing waste.

Dependability

Dependability is critical in any kind of manufacturing process, but it is especially critical when manufacturing vehicles. Dependability plays a huge role in the safety of a vehicle, so automotive manufacturers rely heavily on it throughout the manufacturing process. If automotive makers are unable to manufacture consistent vehicle components, then there is no way they can guarantee safety claims related to the finished product. This is partly why precision machine parts and components are so important in the automotive industry. Ultimately, the most dependable manufacturing is going to happen when machine parts are precisely customized to the manufacturer’s needs. Precision machine parts enable those in the automotive industry to confidently produce consistent and dependable parts. Machine parts are not ‘one-size-fits-all’, so when manufacturing vehicles it’s important for machine parts to be accurate and reliable.

The automotive industry is constantly introducing new innovations and relies heavily on dependable and cost-effective manufacturing processes. Precision machine parts support the automotive industry in its manufacturing processes by providing a customized solution that can adapt with them. These are some of the same reasons why our precision parts can help your business manufacture more effectively.

Content for MagPie Machining by Minieri & Company, LLC, Copyright © 2019-2025, All Rights Reserved.