Industry-Specific Tooling: Lighting Components

Creating industry-specific tooling and parts requires a certain level of knowledge of that industry and its unique requirements.

Magpie Machining offers full-service capabilities to cater to the tooling and machining needs of companies within the lighting industry. For niche companies and manufacturers, it is important to have a reliable, fast and cost-effective way to get the critical parts you need. Magpie Machining has been serving clients in the lighting industry for years, providing them quality parts with fast turn-around times.

Creating industry-specific tooling and parts requires a certain level of knowledge of that industry and its unique requirements. Magpie Machining understands the standards and regulations of critical parts and replacement parts for the lighting industry. A lack of understanding of an industry’s regulations and standards can not only cause malfunctions, but it can also cost a company a lot of time and money correcting any mistakes. Parts, such as metal stamped parts, require a high degree of precision and flexibility for the lighting industry.

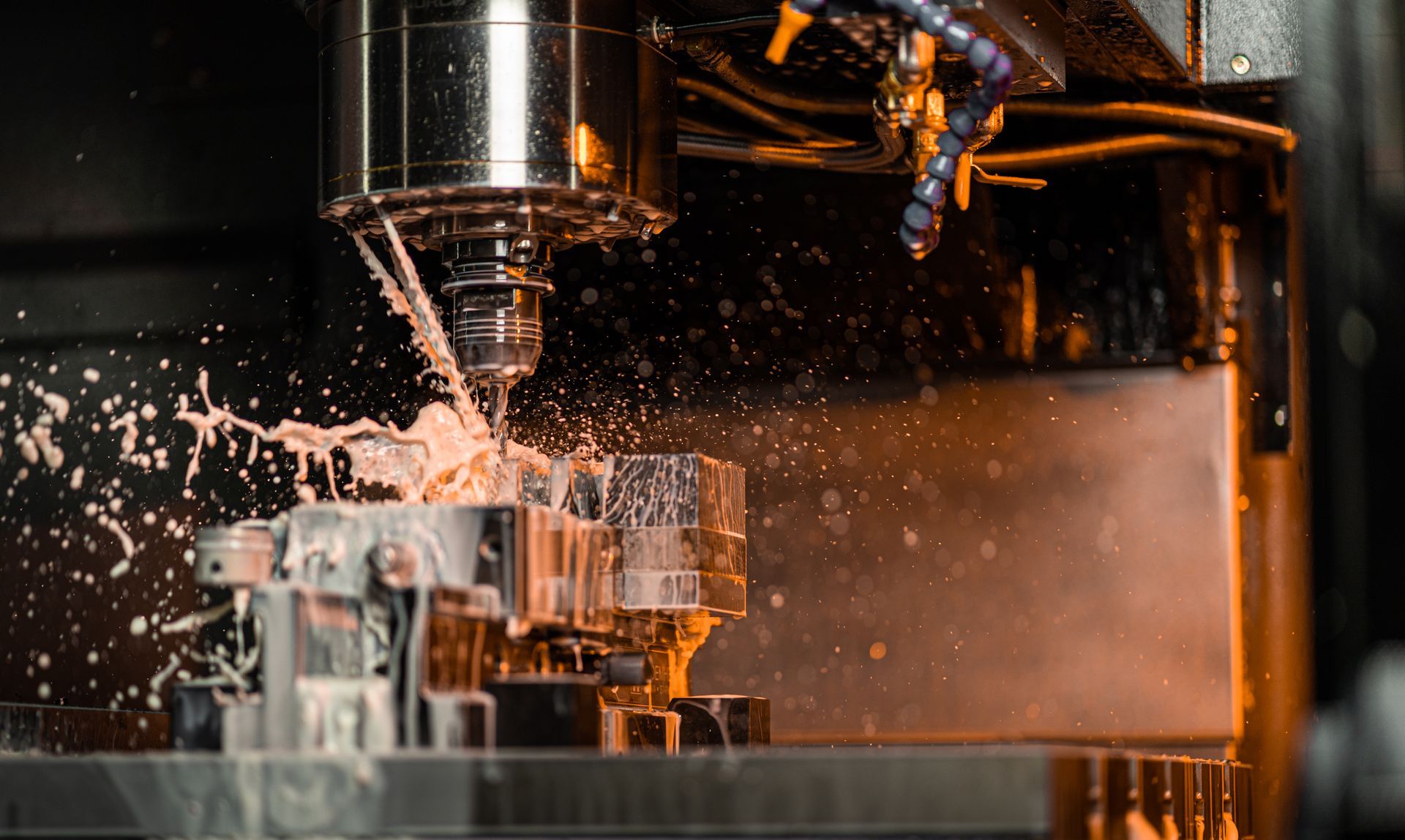

Our experienced personnel and state-of-the-art equipment help to prevent any defects from occurring while maintaining quality precision and flexibility. Our facility, equipment and team are capable of taking on parts regardless of the level of complexity or the size of the run, giving you a cost-effective way to get the parts that you need. We are able to create stamped parts for the lighting industry that include battery cable connectors, heat sinks, inserts, housings, bus bars, brackets, shields and more.

Not only can our team produce tooling for end-use parts, but we can also provide a cost-effective and fast way to assist you with your rapid prototyping processes. Like with most industries, when stamping metal parts for the lighting industry, it is critical to be able to quickly move through each prototyping phase. Being able to rapidly design, assess, modify and produce parts for final production is critical in preventing costly delays. Our rapid prototyping process enables your part to go from design to final production fast.

At Magpie Machining, we can also help clients in the lighting industry develop dies for progressive metal stamping production. Our in-house equipment enables us to obtain fast, optimal results in the design and production of dies. We also utilize quality assurance and quality control procedures to prevent production issues that could slow down your business.

In addition to the stamped components that we are able to produce we also offer comprehensive assembly services to further serve businesses in the lighting industry. We offer in-die assembly as well as secondary semi-automated assembly services. We understand that the needs of companies in the lighting industry are going to differ from companies in other sectors, which is why we take a more targeted approach to serve our customers’ specific needs. From plastic and metal inserts to a variety of hardware components, we are able to assemble these using metal stampings.

If you are in the lighting industry and need a dependable company to assist you with your tooling and metal stamped components, Magpie Machining can provide you quality service with quick turnaround times!

Content for MagPie Machining by Minieri & Company, LLC, Copyright © 2019-2025, All Rights Reserved.