The Basics of Reverse Engineering

Reverse engineering is essentially the process of working backwards to determine the makeup and components of an object or device.

Reverse engineering for manufacturing is just one of the many services that Magpie Machining & Manufacturing offers to its clients. While reverse engineering is not necessarily new, the methods and tools with which to do it have advanced notably in recent years. Many companies do not quite realize the time and money saving benefits that could be obtained by utilizing reverse engineering. In this article, we’ll explain what reverse engineering is and how it can be used to benefit your business.

What is Reverse Engineering?

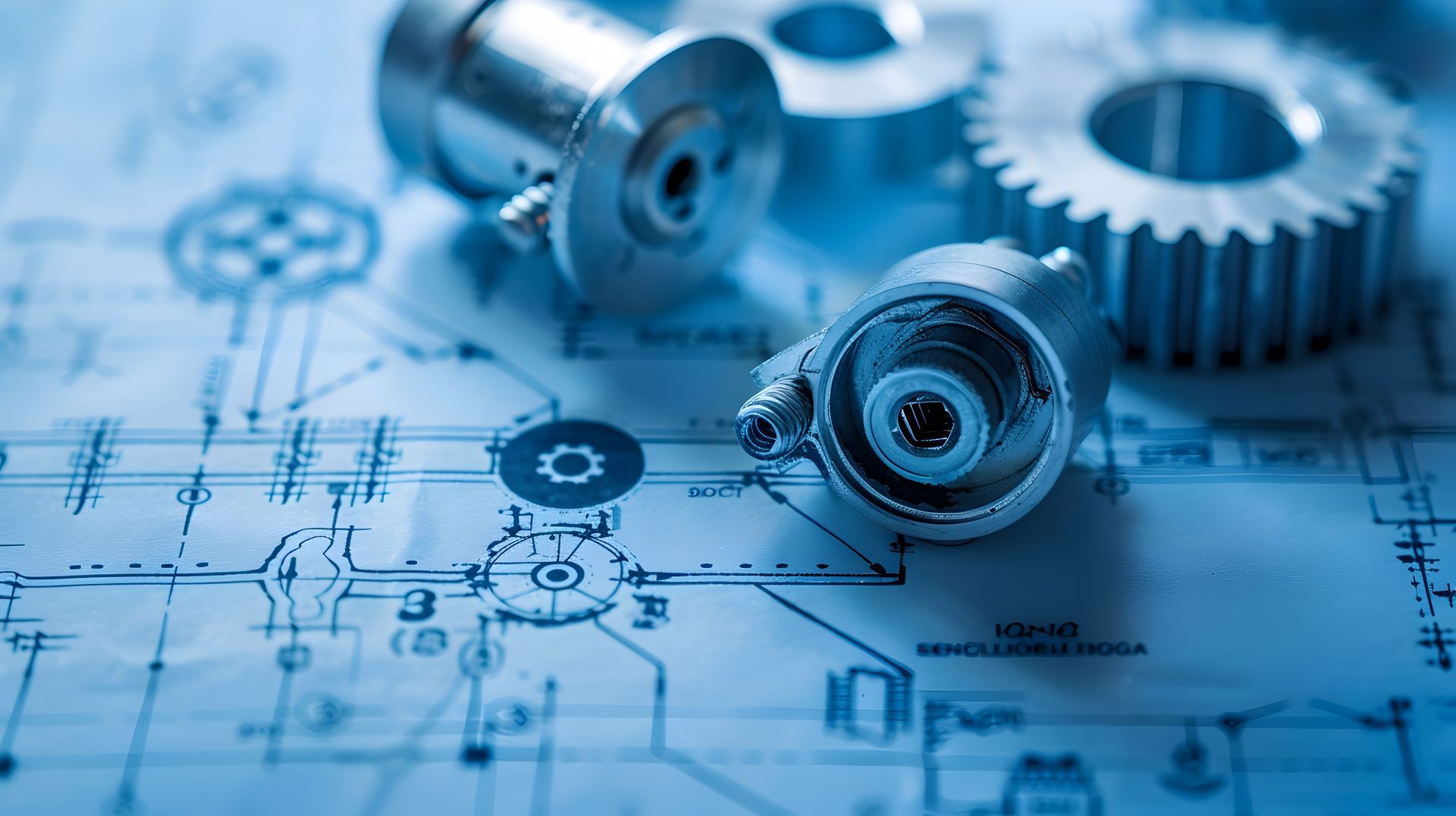

Reverse engineering is essentially the process of working backwards to determine the makeup and components of an object or device. From a manufacturing perspective, reverse engineering consists of dismantling and analyzing a part in order to obtain the measurements and makeup of that part. Magpie Machining & Manufacturing performs reverse engineering by measuring an object and generating a 3D model that represents those measurements. In order for the reverse engineering process to work, it is critical that precise measurements are taken of the entire part or product in order to produce a complete and accurate 3D model. Once measurements of the object are taken, that information is then input into a software, such as a CAD (computer-aided design), CAM (computer-aided manufacturing) or CAE (computer-aided engineering) program. The resulting 3D model can then be used for a variety of things, from documentation to replication.

Why Use Reverse Engineering?

Reverse engineering can be beneficial to nearly every kind of industry and can be applied to nearly any type of part. The benefits of reverse engineering are varied and it is this reason that reverse engineering is a common method utilized by industrial businesses. Reverse engineering is sometimes used to innovate old or outdated parts by analyzing the components and seeing what could be repurposed into new products or parts. Reverse engineering is also beneficial in updating outdated parts by seeing which components are no longer beneficial and therefore should be replaced. Another common use of reverse engineering is to identify any vulnerabilities of a part, which is often easier to do once the part has been disassembled and analyzed. Manufacturers also sometimes depend on reverse engineering to identify potential cost-savings and innovations that could be applied to a part. Lastly, another very common reason that manufacturers and engineers utilize reverse engineering is to generate and obtain digital documentation. It’s not unusual for companies to not have the measurements for parts or products they utilize everyday and when these parts break, it can cause a major interruption in the business’ workflow. Having documentation of critical parts can save a company a lot of time by making it possible to quickly replicate these necessary parts.

Machine shop engineering welding cad custom parts components

Magpie Machining & Manufacturing offers reverse engineering services to allow companies to take advantage of any of these benefits. Whether you have a part that you want to gain more information on or you need documentation of your part’s measurements, Magpie Machining & Manufacturing can quickly reverse engineer your part and get you the critical information you need fast.

Content for MagPie Machining by Minieri & Company, LLC, Copyright © 2019-2025, All Rights Reserved.