What is CNC Machining?

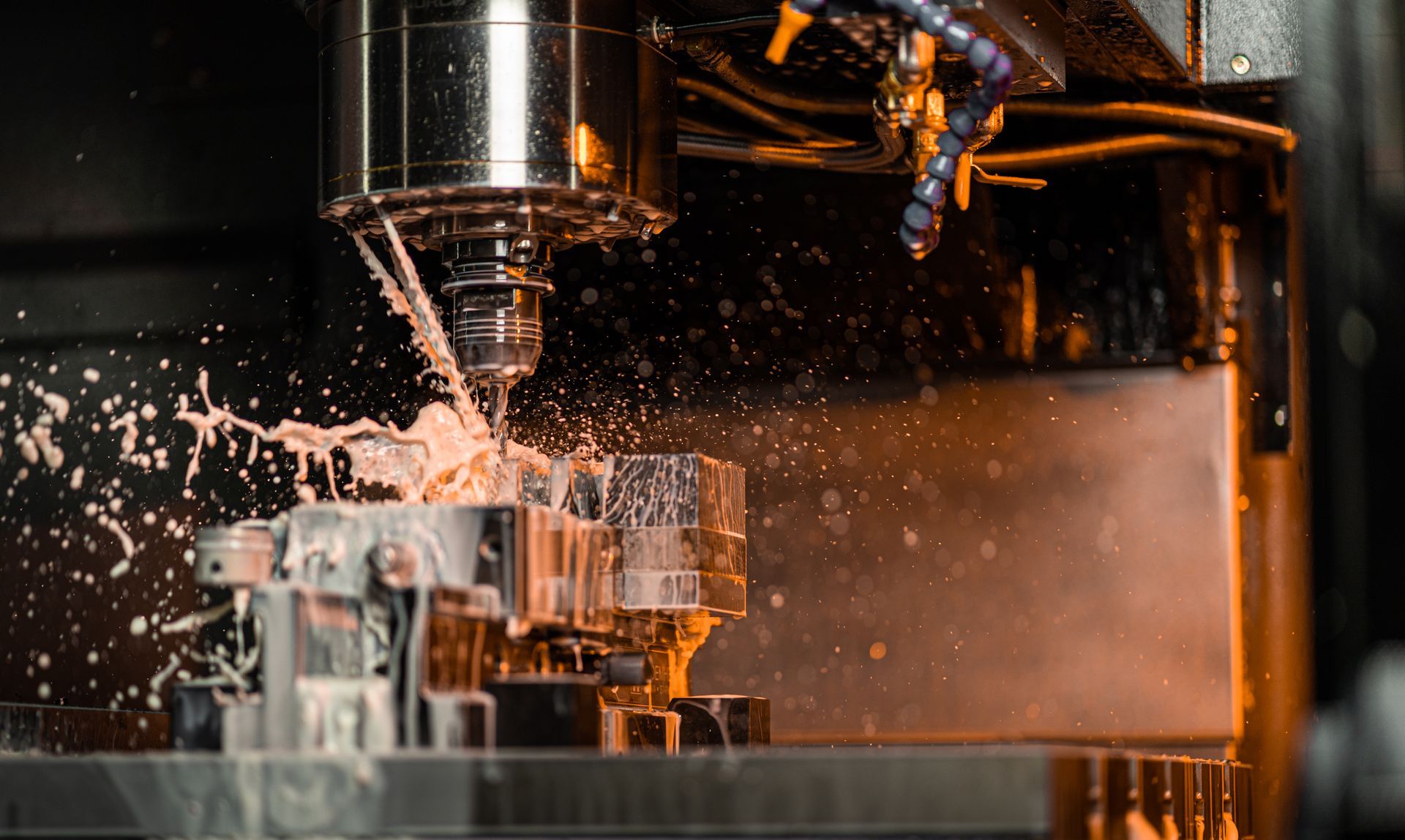

CNC machining is far superior than manual machining due to its high levels of accuracy, consistency and ability to continuously run.

For businesses that require a lot of custom parts there’s one term you’re likely to run across on a regular basis: CNC Machining. CNC machining is a critical component of modern manufacturing. There are many reasons why opting for CNC machining is beneficial, which is why it has become such a mainstay in so many industries. In this article, we’ll go over the basics of CNC machining: What it is and the benefits it provides.

THE BASICS

Before we dive into the benefits of CNC machining, let’s first go over what CNC machining is. CNC stands for computer numerical control and is a process of machining that involves pre-programmed computer software that controls the movement of factory tools and machinery equipment.

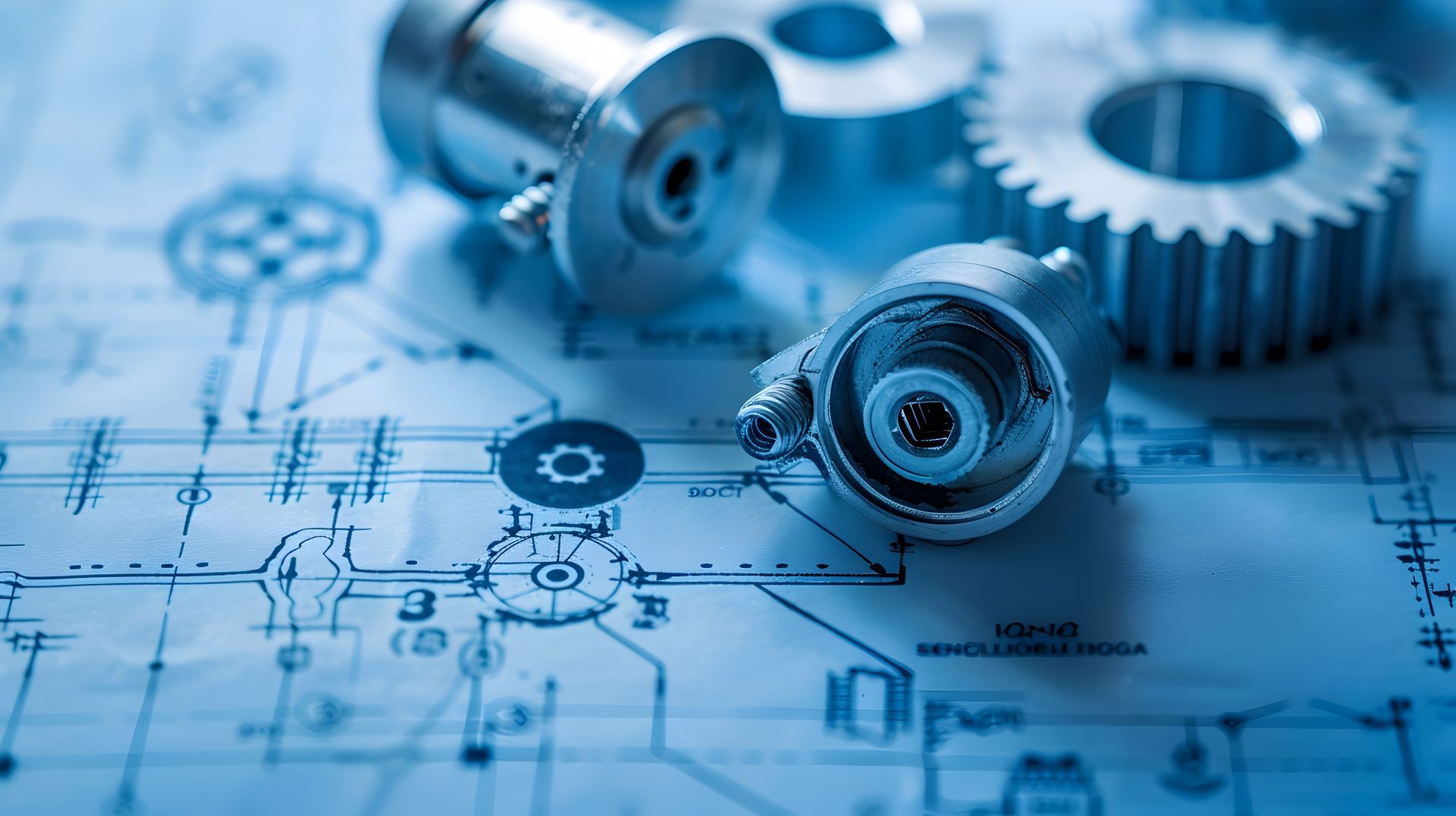

The CNC machining process uses CAD and CAM, which stands for Computer Aided Design and Computer Aided Manufacturing, respectively. CAD and CAM are both a part of the programming process that takes place before a CNC machine can be put into action. First, CAD is used to make a 3D design of the object that must be created. Then, CAM helps convert the design into the necessary requirements of the CNC machine. Everything is programmed prior to the CNC machine being activated. Everything from the speed of each tool, coordination between machines and feed rate have to be correctly programmed in order for the CNC machine to produce the desired object accurately. Once the object’s necessary cuts are programmed, machinery and other corresponding tools will be controlled and moved by the CNC machine. If you’re picturing a manufacturing robot-like machine, then you wouldn’t be too far off. Once programmed, a CNC machine is capable of producing complex parts with laser-like precision, all without the constant supervision and interference of a human.

THE BENEFITS

CNC machining provides a lot of cost and time-saving benefits which is why it has become so desirable for manufacturing. CNC machining provides significantly better control than manually controlling a machine would provide. A big reason why CNC machining provides better control and accuracy is because it removes the risks of human error. Without CNC machining, a human operator would have to be used, which would make producing inconsistent or inaccurate parts a lot more likely. Also, since CNC machining does not have to take into account the risk of human error, it is ideal for consistent, repetitive and predictable machining cycles. Another benefit of CNC machining is that the number of operators needed is reduced compared to what manual machining would require. CNC machining is also a low maintenance process once all of the programming is done and can be run continuously.

CNC machining is a complex process, but when set up by an expert it can have major time and cost-saving benefits. CNC machining is far superior than manual machining due to its high levels of accuracy, consistency and ability to continuously run. At Magpie Machining, we’re able to produce metal and plastic precision parts and custom components, allowing you to reap the benefits of CNC machining without the expensive upfront investment. We utilize high quality and modern equipment to get you the parts you need quickly! Our equipment and machinery includes an Okomato Linear Surface Grinder, Gorton Mastermill manual milling machine, Mori Seiki MV50 8k spindle Vertical Machining Center, Milltronics VM20 15 k spindle Vertical Machining Center and more!

Content for MagPie Machining by Minieri & Company, LLC, Copyright © 2019-2025, All Rights Reserved.