Benefits of CNC Machining in the Energy Sector

The energy sector is vital in powering the world, from traditional fossil fuels to renewable sources like wind and solar. As the demand for more efficient and reliable energy grows, so does the need for precision and innovation in manufacturing components for energy infrastructure. CNC (Computer Numerical Control) machining has emerged as a key technology in this space, offering many benefits that transform how energy components are produced.

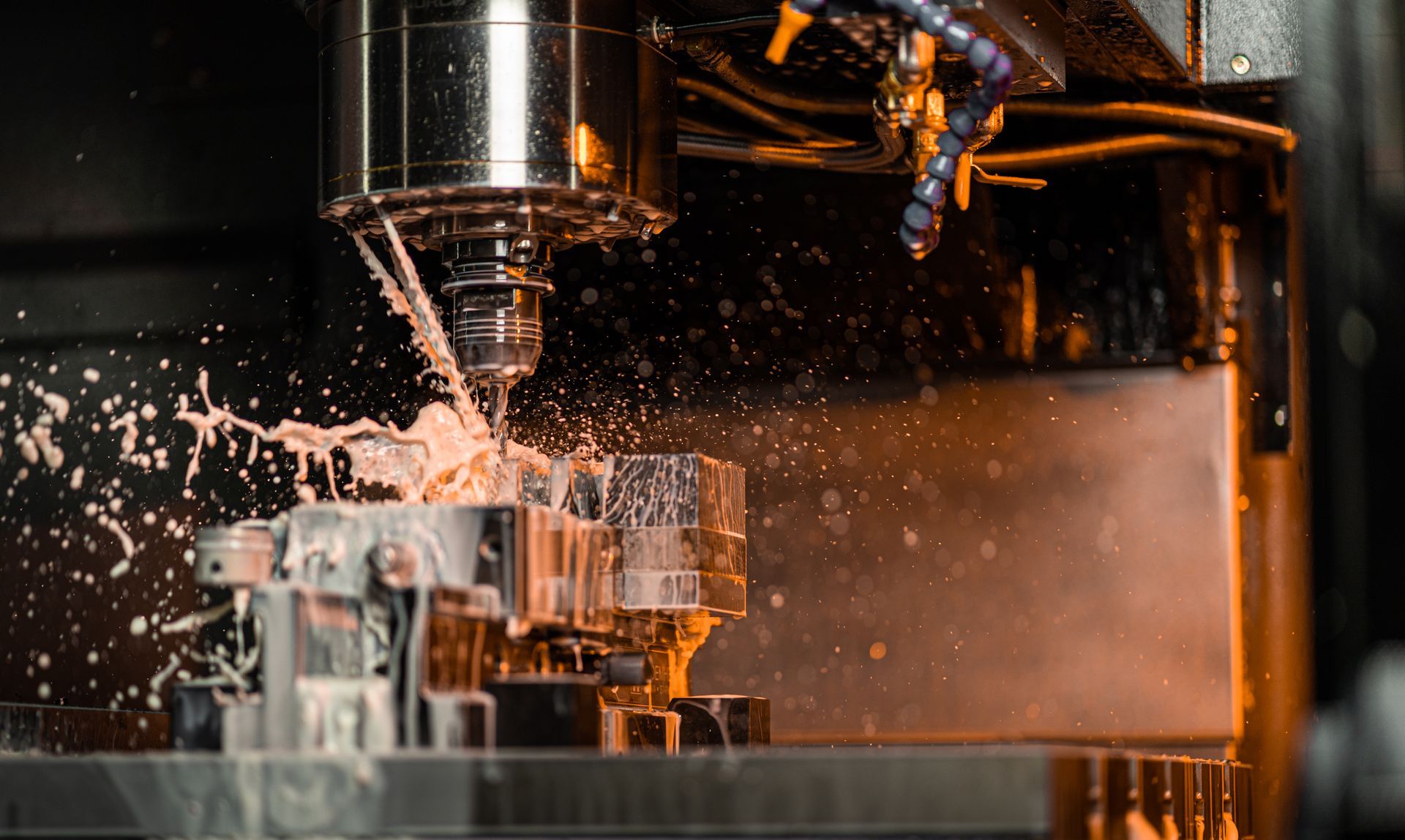

Precision and Accuracy

In the energy sector, precision is everything. Whether creating turbine blades for wind energy or manufacturing components for oil rigs, even the slightest deviation can lead to inefficiencies, downtime, or safety risks. CNC machining excels in delivering high levels of precision and accuracy. Automated CNC machines can manufacture parts to exact specifications with tolerances as tight as a few microns, ensuring that components fit perfectly and function as intended. This level of accuracy is particularly important in industries like nuclear and aerospace energy production, where safety and reliability are paramount.

Material Versatility

The energy industry uses a wide range of materials, from high-strength alloys and composites to more common metals like steel and aluminum. CNC machines can work with various materials, providing flexibility to create parts for different energy applications. Whether manufacturing corrosion-resistant components for offshore oil platforms or creating lightweight parts for solar panels, CNC machining offers the adaptability needed to meet diverse material requirements.

Cost-Effective Production

Cost efficiency is crucial in the energy sector, where large-scale projects often require tight budget control. CNC machining offers a cost-effective production process through automation and repeatability. Once a part design is programmed into the CNC machine, it can be produced at scale with minimal manual intervention, reducing labor costs. Additionally, the repeatability of CNC machining minimizes waste, as parts are consistently manufactured with minimal errors, leading to less material loss.

Speed and Scalability

Companies need to scale production quickly with the growing demand for energy solutions. CNC machining allows for rapid prototyping and production, enabling faster turnaround times from design to final product. Once a design is approved, CNC machines can quickly produce many different parts, ensuring timely delivery for energy projects. This speed and scalability are essential for keeping up with the dynamic demands of the energy market, whether for expanding a wind farm or upgrading infrastructure at a power plant.

Improved Safety and Reliability

Safety is a top priority in the energy sector. Components used in energy production and distribution must meet rigid safety standards. CNC machining ensures that parts are consistently manufactured to high-quality standards, reducing the risk of failure in critical systems. The reliability of CNC-manufactured parts means fewer maintenance issues and less downtime, which is especially important in industries like nuclear and oil, where failures can have catastrophic consequences.

CNC machining offers significant advantages for the energy sector, from precision and material versatility to cost-effective production and improved safety. As the energy industry continues to evolve and innovate, CNC technology will play an increasingly important role in delivering the high-quality, reliable components needed to meet the world’s energy demands.

Content for MagPie Machining by Minieri & Company, LLC, Copyright © 2019-2025, All Rights Reserved.